FiberEdge - Technocrats India

- Home

- /

- FiberEdge - Technocrats India

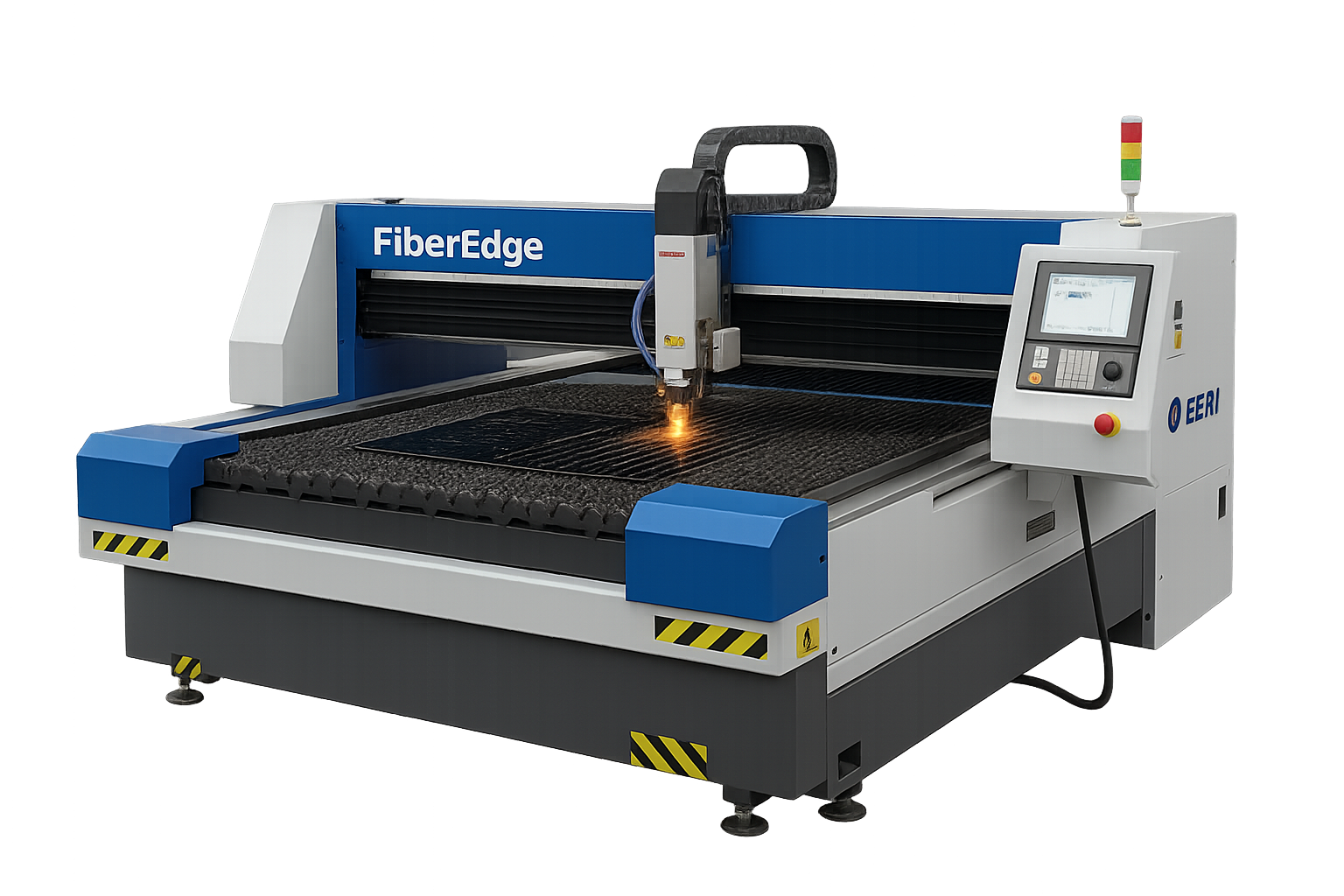

High-Precision Fiber Laser Cutting Machine: Power, Performance & Reliability

Unlock unparalleled precision and efficiency in metal fabrication with our advanced Fiber Laser Cutting Machine. Designed for high-volume production and exceptional cut quality across a wide range of materials, this machine is your ultimate solution for modern manufacturing demands.

Key Features & Configuration Options:

- Powerful Fiber Laser Source: Choose from 1500W, 3000W, 6000W, or 12000W options to match your specific cutting requirements. Our laser sources boast an impressive 100,000-hour lifespan, ensuring stable, cost-efficient, and maintenance-free operation with a remote networking diagnosis system for seamless support.

- Precision Cutting Head: Equipped with leading Raytool / OSPRI / OEM laser cutting heads, featuring a focal length adjustment accurate to 0.01mm, efficient built-in water cooling, and IP65 dust-proof grade for enhanced durability.

- Intelligent CNC System: Powered by Cypcut FSCUT / HYPCUT CNC system, offering a one-stop solution for planning, monitoring, and controlling your production process. Includes basic auto-nesting function for optimized material utilization.

- Automatic Height Adjustment: The non-contact height following function precisely and automatically adjusts the focal length based on the metal plate's height, ensuring consistent and accurate cuts.

- Robust Machine Bed: Features a welded machine bed that undergoes heat treatment and stress relieving processes. Each bed is carefully prepared to ensure internal stress is completely released before precise processing, ensuring maximum load capacity as per laser power.

- Dynamic Motion System:

- PingPong Function: This innovative feature utilizes a swift parabolic path of the laser head, significantly reducing movement time between points and improving mechanical efficiency compared to traditional rectangular movement.

- High-Performance Driving System: Utilizes Panasonic/Yaskawa, Japan servo motors for stable operation, shorter positioning times, and precise control of position, speed, and torque.

- Superior Transmission: Equipped with YYC, Taiwan gear racks and HIWIN, Taiwan linear guides (precision within 0.03mm) for high precision, long service life, and rigorous support for optimal load drive.

- High Output Torque: Features Fuji Z400/X850, Shimpo/Motovario components for high output torque with small rotation clearance, boasting efficiency up to 98%.

- Advanced Gantry Design: The Third Generation Aviation Aluminum Gantry is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. It offers excellent toughness, light weight, corrosion resistance, anti-oxidation, low density, and significantly increased processing speed.

- Efficient Cooling System: Reliable Gem Orion / S&A / Hexacool cooling systems ensure stable performance as per the machine's laser power.

- Integrated Auxiliary Gas Control: Features a comprehensive system for Compress air, Oxygen, and Nitrogen supply, with software control for gas switching and air pressure management.

- Standard Blower: Ensures efficient fume extraction during the cutting process.

Versatile Cutting Capabilities:

This machine is capable of cutting a wide range of metallic materials, including:

- Stainless steel

- Mild steel / Carbon steel

- Copper

- Alloy steel

- Spring steel

- Galvanized plate

- And more!

Diverse Applications:

Ideal for industries such as:

- Aviation & Aerospace

- Electronics & Appliances

- Subway Accessories

- Automobile Manufacturing

- General Machinery & Precision Parts

- Ships & Saw Blades

- Elevators

- Craft Gifts

- Decoration

- Advertising

Technical Parameters (Machine Size Options):

| Items | Technical Parameters |

|---|---|

| Machine Size 3015 | |

| Max Cutting Size (W x L) | 1500 x 3000 mm |

| Effective Travel X axis | 1525 mm |

| Effective Travel Y axis | 3050 mm |

| Effective Travel Z axis | 200 mm |

| Machine Size 4020 | |

| Max Cutting Size (W x L) | 2000 x 4000 mm |

| Effective Travel X axis | 2025 mm |

| Effective Travel Y axis | 4050 mm |

| Effective Travel Z axis | 200 mm |

| Machine Size 6525 | |

| Max Cutting Size (W x L) | 2500 x 6500 mm |

| Effective Travel X axis | 2525 mm |

| Effective Travel Y axis | 6550 mm |

| Effective Travel Z axis | 200 mm |

Basic Common Parameters:

| Items | Technical Parameters |

|---|---|

| Cutting Accuracy | ISO9013 232 |

| Positional Accuracy X axis | ±0.03 mm/m |

| Positional Accuracy Y axis | ±0.03 mm/m |

| Positional Accuracy Z axis | ±0.01 mm/m |

| Repeated Positioning Accuracy X axis | ±0.02 mm |

| Repeated Positioning Accuracy Y axis | ±0.02 mm |

| Repeated Positioning Accuracy Z axis | ±0.005 mm |

| Rapid Positioning Speed X axis | 100 m/min |

| Rapid Positioning Speed Y axis | 100 m/min |

| Rapid Positioning Speed Z axis | 30 m/min |

| Lubrication System | Automatic for LM guide ways |

Cutting Abilities (Max & Quality Cut in mm):

| Laser Source | Metal | Max Cutting Capacity (mm) | Quality Cut (mm) |

|---|---|---|---|

| 1500W | MS | 14 | 12 |

| SS | 6 | 4-5 | |

| Al | 4 | 3 | |

| 3000W | MS | 20 | 16 |

| SS | 10 | 8 | |

| Al | 8 | 6 | |

| 6000W | MS | 25 | 22 |

| SS | 16 | 14 | |

| Al | 14 | 12 | |

| 12000W | MS | 40 | 30 |

| SS | 40 | 30 | |

| Al | 30 | 25 |

Included Accessories (Tool List):

- Machine Consumables (Not in warranty):

- Lower protection glass: 10 pc

- Nozzle: 10 pc

- Ceramic ring: 2 pc

- Protective Eyewear: 1 set

- Lens Cleaning Tools:

- Lens cleaning paper, cloth (lint free cloth): 1 packet

- Lens cleaning bud (10 pieces): 10 pieces

- High purity (>97%) Acetone: 50 ml

- Glove: 5 pc

User's Scope of Supply (Pre-installation Requirements):

To ensure optimal performance and safe operation, the customer is responsible for providing the following:

- Earthing: Two chemical earthing pits close to the machine (resistance < 0.5 Ohm, leakage current < 5mA). Minimum 6 sq mm copper wire for connection.

- Machine Power Supply Cable: As per site requirements.

- Water (for cooling): 50-100L of demineralized water.

- Switch Box: 220V 2 phases, 415V 3 phases, five-wire. (1 pc)

- High-Pressure Pipe Joint: In-line for air compressor. 10mm (2 pc)

- Gas Pipe: Recommended SS pipeline for oxygen & nitrogen from liquid gas tank to machine (contamination must be avoided). As per site requirements.

- Oxygen Cylinder: For MS cutting (O2 @10 Bar). Liquid O2 recommended.

- N2 Cylinder: For SS & other materials (N2 gas @ 22 bar pressure). Liquid N2 recommended.

- Gas Regulators: Required for oxygen & nitrogen depending on cylinder type.

- Air Compressor: Oil & moisture-free compressed air (Pressure: 6-22 Bar, Flow: 20 LPM, 200-500L receiver). (1 pc)

- Online UPS: As per requirement. (1 pc)

- Voltage Stabilizer: As per requirement. (1 pc)

- Isolation Transformer: As per requirement. (1 pc)

- Ducting: As per site requirements.

Environmental Requirements:

- Surrounding Environment: Good ventilation, no impact within 5 meters of the machine.

- Power Voltage: 220V±5%, 415V±5%

- Grounding Type: Centralized directly

Note: The "Fiber Laser Cutting Machine Concept" is for reference only; the actual machine may differ slightly.

Lease / Buy / Enquire

Why Choose us?

- Zero Upfront Cost: Book FiberEdge with no advance payment.

- 15-Year Service Assurance: Unmatched long-term support & spares.

- Flexible Finance, No CIBIL: Get easy leasing tailored to you.

- AI-Powered Remote Support (RAMC): Maximize FiberEdge uptime.

- Online Spares & Payments: Buy all needs, pay your way (PayLater!).

- Direct from 35-Yr Indian Maker (Technocrats): Proven machine quality.

- Exclusive McLease Benefits: Manufacturer can't match our finance/support.

Images

Video

"Zero advance changed everything!" - "We needed a new FiberEdge, but upfront costs were a hurdle. McLease's zero advance until delivery was a game-cha ...

Priya Sharma

Proprietor, Apex Metalworks

"No CIBIL, but got financing!" - "Our CIBIL score wasn't perfect, but McLease looked at our order book, not just old records. Their flexible financing ...

Rajesh Gupta

CEO, Fusion Fab Solutions

"Interest-free leasing is true!" - "We were skeptical about 'interest-free,' but McLease delivered. The structured leasing for our new PANUMA was tran ...

Anjali Singh

Operations Manager, Precision Cut Inc.

"15-year service is pure peace!" - "The 15-year service and spares assurance on our McLease ORBITWELD PRO is unmatched. It’s not just a machine; it's ...

Vikram Reddy

Plant Head, Global Structures Ltd.

"RAMC prevents costly downtime." - "Their AI-Powered Remote AMC (RAMC) is genius. We had a potential issue flagged remotely on our FiberEdge, fixed be ...

Suresh Kumar

Maintenance Director, Bharat Heavy Fab

"ETC streamlined our asset data." - "The Equipment Trust Certificate (ETC) service is a fantastic innovation. It gives us granular, verifiable data fo ...

Deepak Jain

CFO, Industrial Equip. Leasing

"Extra liquidity for our loan!" - "We had a bank loan for our CNC, but needed more working capital. McLease's ETC-backed liquidity provided the perfe ...

Meena Patel

Finance Head, Dynamic Engineering

"Multi-vendor choice is fantastic." - "As a B2B marketplace, McLease offers so many machine options. We compared brands, got the best deal, all in one ...

Alok Verma

Procurement Manager, Steelcraft Auto

"Our private label is top-tier!" - "The quality of McLease's private label machines, like our new McLease PIPETIG AUTO WELD, rivals global brands. 'Ma ...

Rahul Mehta

Production Head, Pioneer FabWorks

"Digital platform, seamless support." - "From ordering spares to raising service tickets, McLease's online hub and app make everything so easy. Digita ...

Geeta Rao

CEO, Smart Fab Solutions

"Expanded reach for our machines." - "Partnering with McLease expanded our market reach instantly. Their financing options are a massive selling point ...

Arjun Devi

Sales Director, Machina-Tech India (Vendor Partner)

"Zero investment, pure profit." - "As a McLease channel partner, there's zero upfront investment. We offer their unique financing and earn transparent ...

Sanjay Das

Channel Partner, Eastern Fabricators

"Superior after-sales support." - "We used to dread post-sales issues. McLease's 15-year service assurance and proactive RAMC on our Cerdi have redefi ...

Kiran Nambiar

Workshop Manager, Precision Metal Arts

"Outcompetes fragmented market." - "McLease cuts through the noise of IndiaMart. They don't just give leads; they offer a complete solution that close ...

Neha Sharma

Business Development Lead, InfraFab Ltd.

"A future-proof ecosystem." - "McLease isn't just a product; it's an ecosystem built for the future. Their ETCs, leasing models, and digital support m ...

Gaurav Singh

Strategic Initiatives Head, NewAge Manufacturing

"Customized solutions for complex work." - "Our McLease GANTRYMIG PRO was customized to our exact specs. The attention to detail and integrated suppor ...

Sameer Khan

Lead Engineer, Aerospace Components

"Consumables on time, every time." - "Ordering consumables and accessories online through McLease is effortless. The reliable supply chain ensures our ...

Puja Das

Procurement Officer, Heavy Industries Corp.

"Seamless integration with our needs." - "McLease understood our need for integrated solutions. Their platform seamlessly connects acquisition, financ ...

Amit Shah

CEO, FabTech Innovations

"Trusted hub for industrial buyers." - "Finding trusted vendors for metal cutting machines was tough. McLease has become our go-to hub, offering quali ...

Ravi Kumar

Head of Sourcing, Large Scale Projects

"Productivity Loss Insurance matters!" - "The Productivity Loss Insurance offered by McLease is a huge relief. Knowing we're protected against machin ...

Sunil Yadav

Factory Manager, Production Giants

"McLease is our gateway to quality!" - "Accessing high-quality machines like FiberEdge in Ghana, with transparent financing and strong support from In ...

Kwame Nkrumah

General Manager, Accra Steel Fab (Ghana)

"Reliable spares, even cross-border." - "Getting genuine spares for our McLease machine used to be a headache. With McLease's online support, we get w ...

Ama Konadu

Chief Engineer, Gold Coast Metals (Ghana)

"Flexible financing, truly global." - "McLease's flexible financing is truly global. It allowed us to acquire advanced welding systems without traditi ...

Ahmed Al-Farsi

Managing Director, Desert Fab Corp (UAE)

"Digital convenience, international scale." - "Managing our machine lifecycle through McLease's digital platform is so convenient. It scales perfectly ...

Fatima Khan

Head of Operations, Emirates Heavy Eng. (UAE)

"Strategic partner for Vision 2030." - "For our ambitious industrial projects aligned with Vision 2030, McLease is a strategic partner, offering innov ...

Bandar Al-Otaibi

Director of Procurement, KSA Industrial Dev. (Saudi Arabia)

"Unparalleled local support presence." - "The commitment to 15-year service assurance and the responsiveness of McLease's support, even here in Saudi ...

Mohammed Al-Dossari

Plant Manager, Arabian Metals Works (Saudi Arabia)

"ETC for asset management clarity." - "The ETC provides crucial transparency for industrial asset management, especially when evaluating machines for ...

Abdullah bin Khalid

Chief Investment Officer, Royal Infra Fund (Saudi Arabia)

"Tailored solutions for complex projects." - "McLease's ability to offer customized automated welding systems, like the McLease FINWELD PRO, with comp ...

Noura Al-Hajri

Project Lead, Future City Fab (Saudi Arabia)

"Seamless integration with our ecosystem." - "McLease integrates seamlessly into our procurement and operational ecosystem, offering not just machines ...

Omar Hassan

CEO, Kingdom Precision Eng. (Saudi Arabia)

"Building long-term trust and value." - "Beyond transactions, McLease builds long-term trust. Their commitment to continuous support and innovative fi ...

Khalid Al-Hamad

CEO, Gulf Heavy Machinery (Saudi Arabia)